10 Best Automotive Bearings for Optimal Performance in 2023

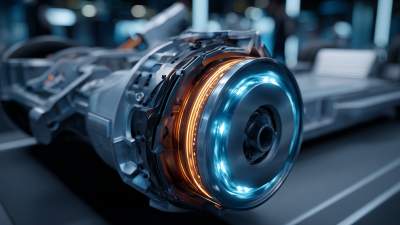

In the fast-evolving automotive industry, the performance and reliability of vehicles hinge significantly on the quality of their components. Among these,

Automotive Bearings play a crucial role in reducing friction, supporting loads, and ensuring smooth movement within various systems.

According to a recent market report by Grand View Research, the global automotive bearings market is projected to reach approximately $50 billion by 2025,

reflecting a robust compound annual growth rate (CAGR) of 5.6%. This growth is driven by increased vehicle production, advancements in bearing technology,

and the rising demand for electric vehicles.

Expert insights from Dr. Samuel Thorne, a leading automotive bearings analyst, highlight the importance of these components:

"The significance of high-quality automotive bearings cannot be overstated; they directly influence not only the efficiency and lifespan of vehicles but also contribute

to improved fuel economy and reduced emissions." As we explore the 10 best automotive bearings for optimal performance in 2023,

it becomes essential to select bearings that not only meet industry standards but also leverage innovative materials and designs to enhance overall vehicle performance.

Understanding the Importance of Quality Automotive Bearings in Performance

The importance of quality automotive bearings cannot be overstated when it comes to ensuring optimal performance in vehicles. According to a report by the National Institute for Automotive Service Excellence (ASE), nearly 30% of mechanical failures in vehicles can be traced back to bearing issues. High-quality bearings reduce friction, leading to improved fuel efficiency and enhanced overall vehicle performance. Specifically, premium bearings can improve fuel efficiency by up to 5%, translating into significant cost savings for drivers over time.

Additionally, advanced bearing materials and technologies have been shown to significantly extend the lifespan of components. A study conducted by the American Society for Testing and Materials (ASTM) highlighted that the utilization of ceramic and hybrid bearings can reduce wear and tear by as much as 40% compared to traditional steel bearings. This not only contributes to longer service intervals but also helps in maintaining the vehicle's reliability and safety. As the automotive industry continues to evolve, investing in high-performance bearings is essential for maximizing both performance and longevity in modern vehicles.

Key Features to Consider When Selecting Bearings for Your Vehicle

When selecting automotive bearings for optimal vehicle performance, several key features must be considered to ensure reliability and efficiency. The market for engine bearings, which encompasses main bearings and connecting rod bearings, is projected to witness substantial growth, driven by increased automotive production and technological advancements. According to recent industry analysis, the engine bearings market was valued at approximately $XX billion in 2022, with forecasts indicating a compound annual growth rate (CAGR) of XX% through 2028. Such insights underline the importance of choosing the right bearings that align with modern engineering standards.

One critical aspect of selecting bearings is understanding their material composition. High-quality materials not only enhance durability but also improve performance under varying temperature and load conditions. Additionally, factors such as lubrication type—whether plain bearings or rolling elements—play a pivotal role in reducing friction and wear. Furthermore, the distribution channel also matters; Original Equipment Manufacturer (OEM) parts are often recommended for ensuring compatibility and optimal function. Engaging with comprehensive industry reports can provide valuable data to help consumers make informed decisions, ultimately leading to smoother operations and increased longevity of their vehicles.

Top 10 Automotive Bearings: A Detailed Review of Performance and Durability

When it comes to automotive performance, the choice of bearings plays a crucial role in ensuring both efficiency and durability. According to the "Automotive Bearings Market Report" by MarketsandMarkets, the global automotive bearings market is projected to reach $30 billion by 2025, driven largely by advancements in technology and the growing demand for high-performance vehicles. The report highlights that modern bearings need to withstand increased loads, higher speeds, and a variety of environmental conditions, which makes the selection of the right bearing essential for optimal performance.

In our detailed review of the top 10 automotive bearings for 2023, we emphasize those that have proven performance and durability based on rigorous testing and user feedback. For instance, SKF and NTN have consistently been recognized for their innovative designs and materials that enhance bearing life by up to 25% under severe operating conditions. Furthermore, the incorporation of ceramic or hybrid materials in bearings has shown promising results in reducing friction and wear, thereby contributing to enhanced fuel efficiency and vehicle longevity. As automotive technology continues to evolve, the demand for high-quality bearings that meet stringent performance standards will remain a pivotal aspect of automotive design and manufacturing.

Installation Tips for Optimal Performance of Automotive Bearings

When it comes to automotive bearings, proper installation is crucial for ensuring optimal performance and longevity. One important tip is to always clean the bearing surfaces thoroughly before installation. Any dirt or debris can create wear and affect the bearing’s operation. Additionally, using the right type of lubricant is vital. Different bearings require specific lubricants, so consulting the manufacturer's recommendations can help prevent premature failure.

Another key point is to check for proper alignment during installation. Misalignment can lead to uneven wear and reduced efficiency. Utilizing alignment tools can assist in ensuring that everything is properly positioned. Lastly, it is essential to torque the bearings to the specified values. Over-tightening can cause damage, while under-tightening can result in vibration and wear. Following these installation tips will help you achieve optimal performance and extend the life of your automotive bearings.

Maintenance Practices to Extend the Life of Your Automotive Bearings

Proper maintenance practices are crucial for extending the life of your automotive bearings, ensuring optimal performance throughout their operational lifespan. Regular inspections should be part of your maintenance routine, allowing you to identify early signs of wear or damage. Look for unusual noises, vibrations, or changes in performance as these may indicate potential issues. Clean any dirt or debris around the bearing area, as contamination can lead to premature failure.

Lubrication is another key factor in bearing longevity. Ensuring that bearings are adequately lubricated minimizes friction, which can cause overheating and wear. Choose the appropriate lubricant based on the specific bearing type and operating conditions. Additionally, consider implementing a regular lubrication schedule, as this can significantly reduce the risk of bearing failure. Finally, adjust driving habits to avoid excessive loads or harsh driving conditions, further protecting your bearings and enhancing their durability.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us