How to Choose the Right Agricultural Bearings for Your Farming Needs

When it comes to optimizing farming operations, selecting the right Agricultural Bearings is crucial for ensuring machinery efficiency and longevity. According to a report by Research and Markets, the global agricultural bearings market is projected to reach $12.5 billion by 2026, reflecting the growing importance of high-quality components in agricultural machinery.

The right bearings can significantly reduce downtime and maintenance costs, which are essential for farmers aiming to maximize productivity in an industry that faces increasing pressure from fluctuating prices and climate variability. With a myriad of options available, understanding key factors such as load capacity, environmental conditions, and materials is essential for making informed decisions that align with specific farming needs.

This guide aims to provide crucial insights into how to choose the most suitable Agricultural Bearings to enhance operational efficiencies and ensure sustainable farming practices.

Understanding Different Types of Agricultural Bearings and Their Applications

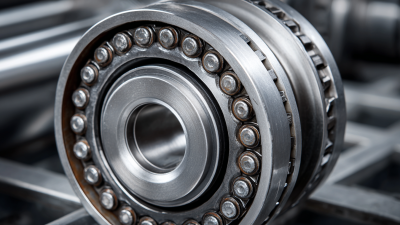

When it comes to agricultural operations, selecting the right type of bearing is essential for ensuring equipment efficiency and durability. Agricultural bearings come in various forms, each designed to meet specific applications within farming machinery.

For example, deep groove ball bearings are widely used due to their versatility and ability to handle both radial and axial loads. They are suitable for applications in tractors, combines, and other general farming equipment.

Another important type is tapered roller bearings, which excel in applications requiring heavy load-bearing capabilities. These bearings are commonly found in the wheel hubs of vehicles, where they manage high levels of stress during operation.

Additionally, spherical bearing units are designed to accommodate misalignment, making them ideal for applications involving rotary equipment such as augers and conveyors. Understanding these differences not only helps in choosing the right bearings but also aids in prolonging the lifespan of farming machinery, ultimately leading to improved productivity in agricultural operations.

Key Factors to Consider When Selecting Bearings for Farming Equipment

When selecting bearings for farming equipment, several key factors must be considered to ensure optimal performance and longevity. First, it’s essential to evaluate the operating environment in which the bearings will be used. Factors such as exposure to moisture, dust, and chemicals can greatly impact bearing selection. For instance, if the equipment operates in wet or corrosive conditions, bearings made from stainless steel or those with protective coatings will offer better durability.

Another crucial aspect to consider is the load capacity and speed requirements of the equipment. Bearings are designed to handle specific loads, and exceeding these limits can lead to premature failure. It's important to understand the weight and stress the bearing will endure during operation. Additionally, bearings must be compatible with the rotational speed of the equipment; choosing the wrong type can lead to overheating and inefficiency. By carefully assessing these factors, farmers can select bearings that enhance the reliability and efficiency of their machinery, ultimately leading to improved productivity on the farm.

Assessing Load Capacity and Speed Requirements for Agricultural Bearings

When selecting agricultural bearings, assessing load capacity and speed requirements is crucial for ensuring optimal equipment performance. According to a report by the American Society of Agricultural and Biological Engineers, the average load encountered by bearings in agricultural applications can range significantly, from 1,000 to over 10,000 pounds, depending on the machinery. Understanding the specific load conditions your equipment will face is vital; for example, bearings used in heavy-duty tillage equipment require higher load capacities compared to those in lighter seeders.

Additionally, speed is another key factor to consider. The operational speed of agricultural machinery typically varies, with most equipment operating between 200 to 1,500 RPM. A study by the International Journal of Agricultural Engineering indicates that bearings designed for lower-speed applications, such as plows and harrows, may not perform adequately at higher revolutions per minute found in harvesting equipment. Thus, selecting the right bearing that can withstand both the load requirements and speed operations is essential to prevent premature wear and failure, ultimately enhancing productivity and efficiency on the farm.

Identifying the Environmental Conditions Impacting Bearing Performance

When selecting agricultural bearings, understanding the environmental conditions that can impact their performance is essential. Factors such as humidity, temperature fluctuations, and exposure to chemicals and dust can significantly influence the longevity and reliability of bearings in farming equipment. For instance, bearings in wet or damp environments require special sealing and materials to prevent corrosion and ensure optimal functionality.

Tips: Always opt for bearings specifically designed for agricultural use, as they are engineered to withstand challenging conditions. Regularly inspect the seals and lubrication levels, as these play a crucial role in protecting bearings from environmental stressors.

Additionally, the type of crop being cultivated can affect the demands placed on the bearings. For example, operations that involve heavy, abrasive materials may require bearings with higher load capacities and enhanced durability. Understanding the specifics of the environment and operations not only helps in choosing the right bearings but also in extending their service life and maintaining equipment efficiency.

Tips: Consider investing in bearings with stainless steel or ceramic elements for enhanced resistance to harsh environments. Regular maintenance checks can also help in identifying potential issues before they lead to costly downtimes.

Maintenance Tips to Ensure Longevity of Agricultural Bearings in Use

Proper maintenance of agricultural bearings is crucial for ensuring their longevity and optimal performance in farming equipment. Regular inspection is essential; operators should examine bearings for signs of wear, such as discoloration, excessive play, or unusual noise. Addressing these issues early can prevent further damage and costly downtimes. It's also important to clean the bearings periodically to remove dirt and debris that can cause additional friction and wear. Using appropriate cleaning agents and methods will help maintain the integrity of the bearing materials.

Lubrication plays a significant role in the lifespan of agricultural bearings. Choosing the right lubricant, whether grease or oil, tailored to the specific operating conditions can greatly enhance bearing performance. Implementing a consistent lubrication schedule ensures that bearings remain adequately protected from wear and tear. Additionally, monitoring the lubricant’s condition and replenishing it as needed can prevent contaminants from compromising the bearings. By adopting these maintenance practices, farmers can extend the life of their agricultural bearings, reducing replacement costs and improving overall equipment reliability.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us