PU/POM Rubber Coated Bearings: Selection & Applications

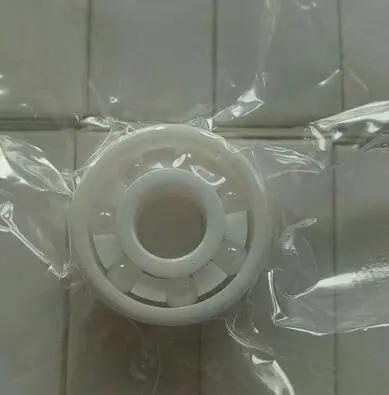

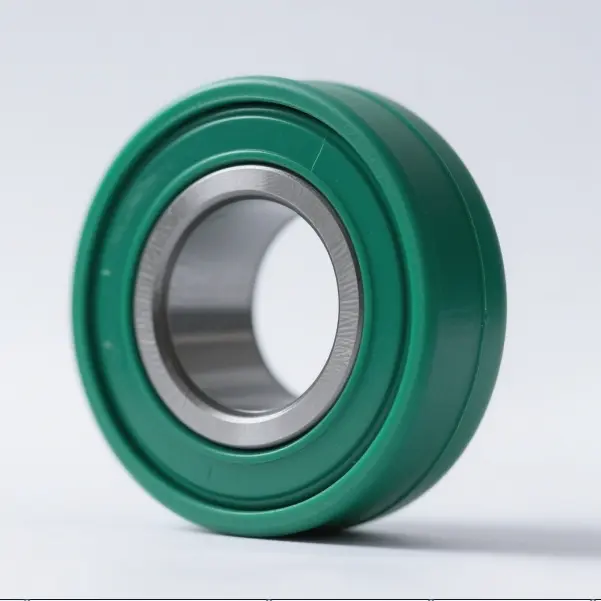

Rubber-coated bearings

It refers to special non-standard bearings that use a casting or injection molding process to form a layer of rubber products on the outer ring of the bearing by pressing or bonding.

Advantages and classification of rubber-coated bearings

Rubber-coated bearings have excellent strength, wear resistance, heat resistance, hydrolysis resistance, and aging resistance. They have a bright appearance and a fine and smooth colloid surface. The outer ring of the bearing is sandblasted to ensure that the colloid shell and the shaft core are firmly bonded and not easily damaged. GnB ‘s rubber-coated bearings have a variety of hardness options. Compared with ordinary bearings, rubber-coated bearings have the advantages of impact resistance and low noise.

Commonly used rubber coating materials are as follows:

①-Polyurethane(PU)

Good chemical properties, good solvent resistance,

Anti-aging, tear resistance, good resilience.

②-Rubber

Good heat resistance, cold resistance, ozone resistance and atmospheric aging resistance,

Disadvantages are poor mechanical properties such as tensile strength and tear strength,

Poor oil resistance and organic solvent resistance.

③-Polyacetal (POM)

High mechanical strength, high rigidity, high fatigue strength,

Good organic solvent resistance, strong wear resistance,

Disadvantages are poor acid resistance, large forming shrinkage, and easy to decompose under long-term high temperature. In addition, GnB rubber-coated bearing products also have rubber-coated materials such as nitrile rubber neck and fluororubber to choose from.

Process sharing of rubber-coated bearings

Injection molding type (TPU)

It is solid before molding,

It can be mass-produced, with high efficiency and low cost,

It is cost-effective to use it as a guide alone.

Casting type (CPU)

It is liquid before molding,

The range of raw material selection is wider, and the product hardness range is wider.It is particularly suitable for the production of large and medium-sized products,

It makes up for the limitations and shortcomings of the processing technology of TPU products. The products using the casting process have better compressive resistance.

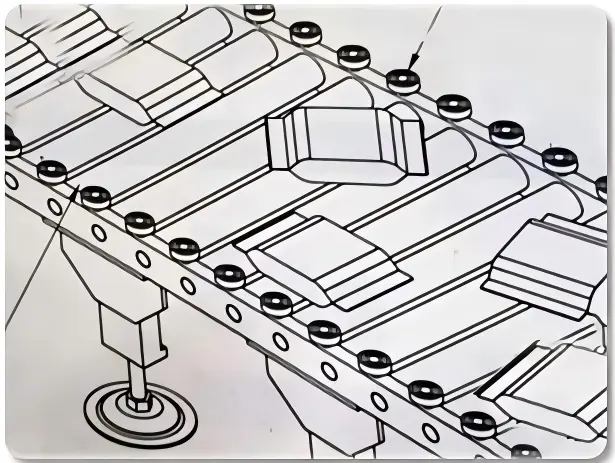

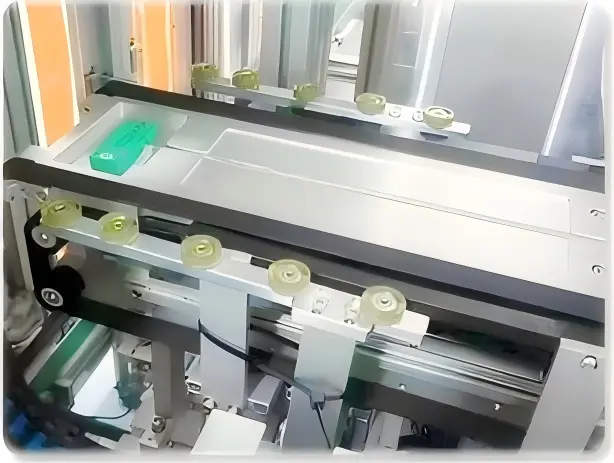

Operating conditions of rubber-coated bearings

Transfer the bagged products to the next process

Transfer the bagged products to the next process

Support and guidance of the swing arm of the coating machine

Support and guidance of the swing arm of the coating machine

Guided conveying of silicon wafers

Guided conveying of silicon wafers