-

Home

-

Products

-

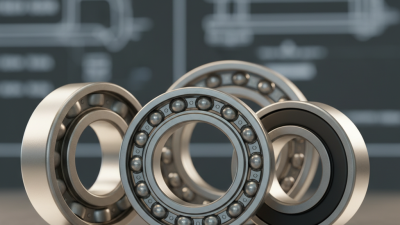

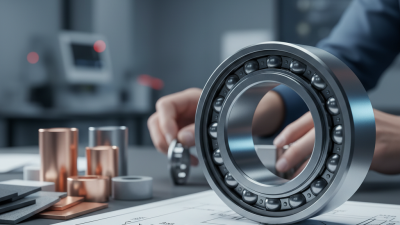

Industrial Bearings

-

Deep Groove Ball Bearings

-

Self-Aligning Ball Bearings

-

Angular Contact Ball Bearings

-

Cylindrical Roller Bearings

-

Taper Roller Bearings

-

Spherical Roller Bearings

-

Bearing housing or Accessories

-

Miniature Bearing

-

Thrust ball bearing

-

Radial Spherical Plain Bearing

-

Pillow Block Bearing

-

Needle Roller Bearings

-

-

Automotive Bearings

-

Agricultural Bearings

-

Special Material Bearings

-

-

Industry Application

-

About Us

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp